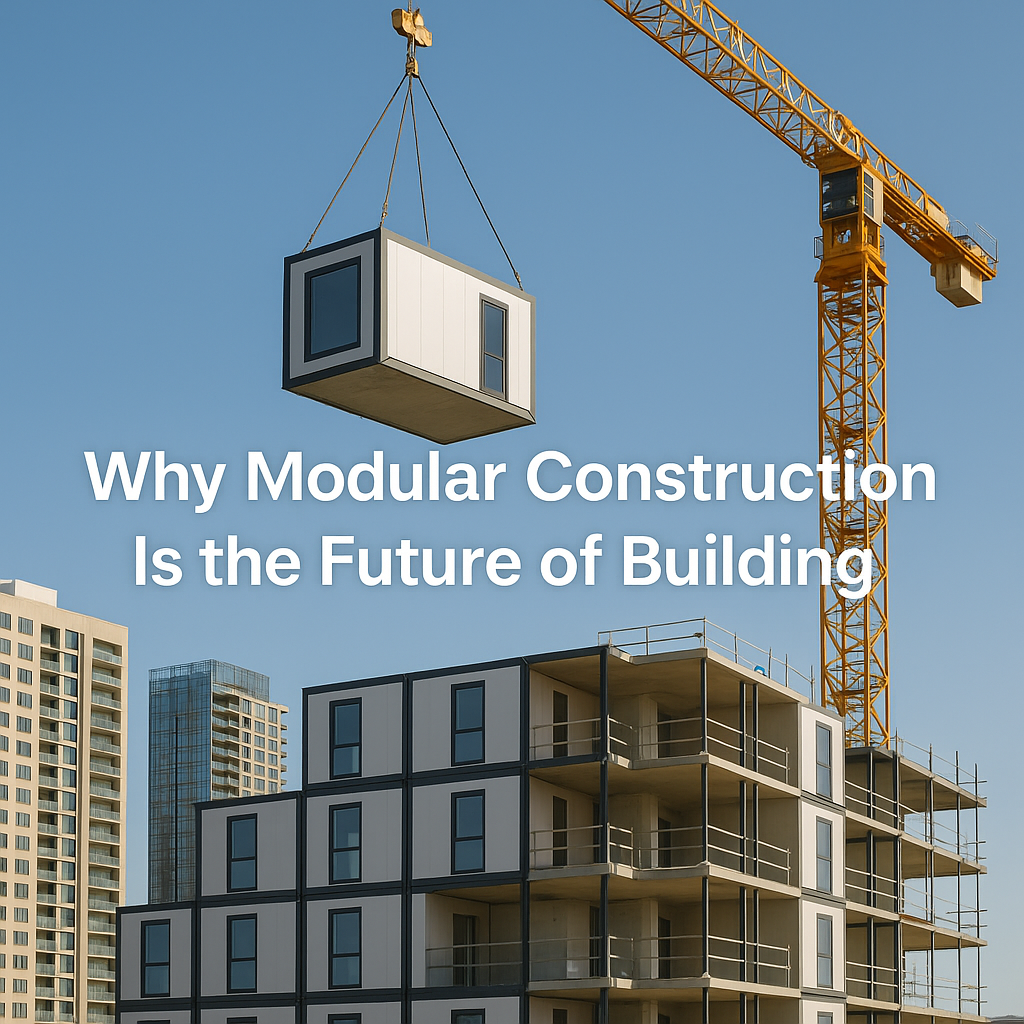

The global construction industry is undergoing a dramatic transformation — and modular construction is at the center of it. With rising labor costs, supply-chain challenges, and tight project timelines, traditional construction methods are struggling to keep pace with modern demand.

Prefabricated construction, where building components are manufactured off-site and assembled on-site, is proving to be faster, cleaner, and more sustainable. According to Future Market Insights (2024), the global modular and prefabricated construction market will surpass $210 billion by 2035, growing over 5.7% annually.

In other words — modular construction isn’t just the future of building. It’s already here.

What Is Modular and Prefabricated Construction?

Modular construction refers to creating standardized building modules — like wall panels, bathroom pods, or full rooms — in a controlled factory environment. These modules are transported and assembled on-site to create a complete structure.

This method offers key advantages:

- Fewer delays (since work happens indoors)

- Higher quality control

- Reduced material waste

- Improved safety conditions

Unlike traditional builds, modular projects allow design, engineering, and production to occur simultaneously — drastically reducing total build time.

Why Modular Construction Is Taking Off

- Faster Timelines

One of the most powerful advantages of off-site construction is speed. Because modules are built in factories while foundations are prepared on-site, total project duration can be cut by 30%–50%.

For example, a 309-day modular project timeline — from permit to completion — is now standard, compared to 18–24 months for conventional builds.

- Cost Efficiency

With global construction costs up more than 30% since 2020, modular approaches deliver major savings. Prefabrication minimizes on-site labor, weather delays, and waste — producing predictable budgets and faster ROI.

Even large-scale industrial projects, like U.S. LNG facilities (Reuters, Sept 2025), are shifting to modular to offset material and labor inflation.

- Superior Quality Control

In a factory, every component is inspected under consistent conditions — something nearly impossible on open-air job sites.

This ensures tighter tolerances, better energy performance, and fewer post-occupancy defects.

- Sustainability and Waste Reduction

Modular projects can reduce construction waste by up to 80%, thanks to precision manufacturing and standardized material use.

Less waste, fewer deliveries, and shorter on-site time also mean lower carbon emissions — a win for green-building goals.

- Safety and Worker Efficiency

Because 60%–90% of work happens indoors, workers face fewer weather-related risks and injuries. Factory environments improve safety and consistency while enabling year-round production.

Real-World Modular Construction Success Stories

Norwalk Multifamily Modular Project (U.S.)

One of the largest residential modular builds in North America — a 58-unit affordable housing development — was completed in record time using volumetric modules (Modular.org, 2024).

Habitat 67 (Canada)

A pioneer of modular architecture, this iconic Montreal complex demonstrated how prefabrication could blend design innovation with scalability — long before the trend went mainstream.

Industrial Energy Facilities (U.S.)

Large-scale infrastructure, including LNG export terminals, are now using modular construction to cut costs and deliver projects ahead of schedule (Reuters, 2025).

Challenges Slowing Wider Adoption

Despite its growth, modular construction faces several challenges:

- Up-front design requirements — modular projects demand early collaboration.

- Transportation logistics — moving large modules requires careful planning.

- Regulatory barriers — building codes still lag behind modular innovation.

- Perception issues — some developers still associate “modular” with “temporary.”

However, as supply chains mature and digital tools advance, these barriers are rapidly diminishing.

Key Takeaways

- Modular construction is faster, cleaner, and greener than traditional methods.

- Factory production ensures better quality and less waste.

- Market growth is accelerating across residential, commercial, and industrial sectors.

- Early adopters — developers, architects, and investors — will lead the next construction revolution.

Modular and prefabricated construction offer faster timelines, predictable costs, and sustainable outcomes. With global demand for housing and infrastructure rising, modular methods will dominate the future of building — driven by innovation, digital design, and growing investor confidence.

FAQ: Modular Construction Explained

Q1: Is modular construction cheaper than traditional?

Yes — especially when factoring in reduced delays, lower labor costs, and faster project turnover.

Q2: Can modular work for large or high-rise buildings?

Absolutely. Modern modular systems are being used for hotels, hospitals, and towers exceeding 30 floors.

Q3: How does modular support sustainability?

Less waste, reduced carbon footprint, and improved material efficiency make modular construction a key tool for green development.

Q4: What industries benefit most?

Residential, hospitality, education, healthcare, and energy sectors are leading adopters.